REBUILD PROCEDURE

Ampco’s ZP style remanufacturing program has earned an excellent reputation for quality and delivery since it was introduced in 2010. Our central location in Milwaukee, WI minimizes shipping time and expense. Our focused remanufacturing facility offers a two week turnaround from the time you issue a purchase order so potential downtime is minimized. Remanufacturing will restore your ZP style pump ( all models from the 06 to the 320) to its original performance and efficiency and offers significant cost savings.

Remanufactured pumps include all standard Ampco upgrades (except a stainless steel gear case), are performance tested before shipment and carry a full one-year factory warranty. Extend the life of your existing pump by sending the pump to Ampco to be remanufactured. Your pump can be returned to "like new" condition in two weeks saving you valuable time and money. Standard rebuild time is two weeks once pumps are received. View Available Rebuild Procedures |

|

ADVANTAGES OF THE AMPCO PUMP REMANUFACTURING PROGRAM:

- Centrally located to minimize shipping cost and downtime

- Two week turnaround from the time you issue a purchase order

- Gear case is sandblasted and powder coated

- Pump body and cover are re-machined to bring back original tolerances and efficiency *

- New over-sized Alloy 88 rotors

- Same upgrades as new Ampco ZP pumps

- 17-4ph shafts

- Stainless steel bearing retainers

- Helical gears

- Anti-microbial lube

- Gasketed clean-out plugs

- Completed pump is performance tested

- Up to four standard rebuilds (.020, .040, .060, .080 oversized) on ZP1 style pumps

- Up to three standard rebuilds (.020, .040 and .060 oversized) on ZP2 style pumps+

- Machine housing and cover to accommodate oversized rotors.

- Recondition gear case including powder coating finish.

- Replace all other parts including rotors, shafts, bearings, bearing retainers, gears, jam nuts / rotor nuts, seals and elastomers.

- Performance test before shipment.

- One year warranty.

- Price is 70% of new pump price

- Possible adders: We will notify you if the housing, cover, gear case or ferrules are not salvageable or if the pump requires excessive clean-up

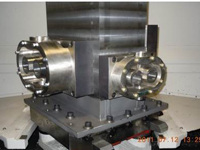

PUMP REMANUFACTURING PROCESS:

Step 1 - We completely tear down the pump. All internal components; shafts, bearings, gears, spacers, seals, etc. are removed and replaced with new components.

Step 2 - We machine body and cover to standard oversized dimensions; +.020, .040, .060, .080.

Step 3 - Body and Cover are polished back to their original 32 RA finish.

Step 4 - We machine new oversized rotors to bring back tolerances to match new pump performance/efficiency.

Step 5 - Pumps are assembled to the same factory specified tolerances of a new pump. Pumps are assembled less seals/elastomers until Customer specifies option.

Step 6 - Pumps are 100% water-tested before shipment to assure flow requirements are met, as well as seal leakage. All pumps carry a one year warranty; same warranty as a new Ampco pump.